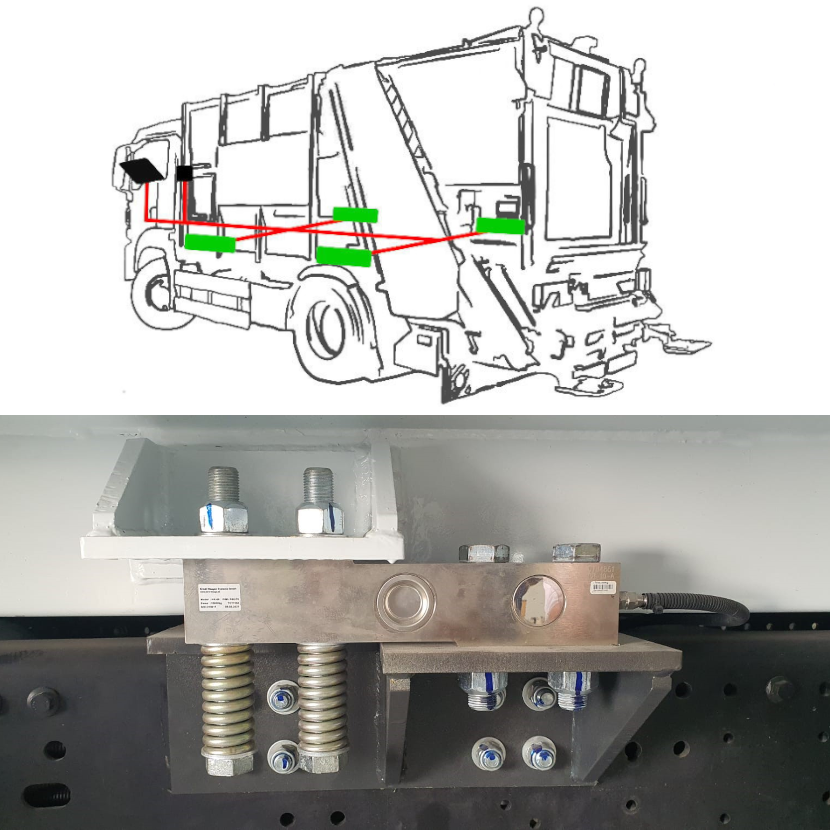

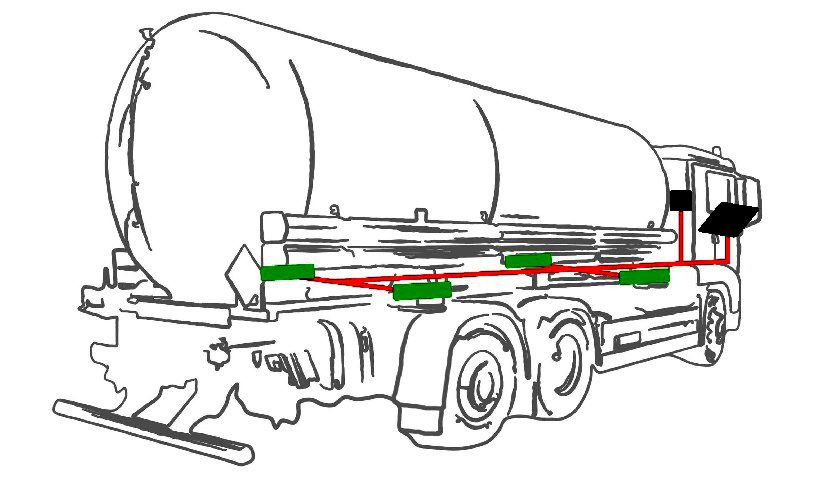

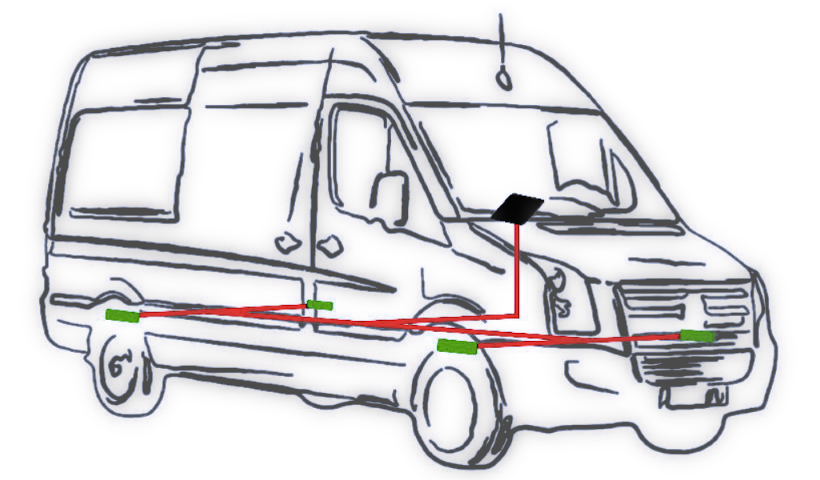

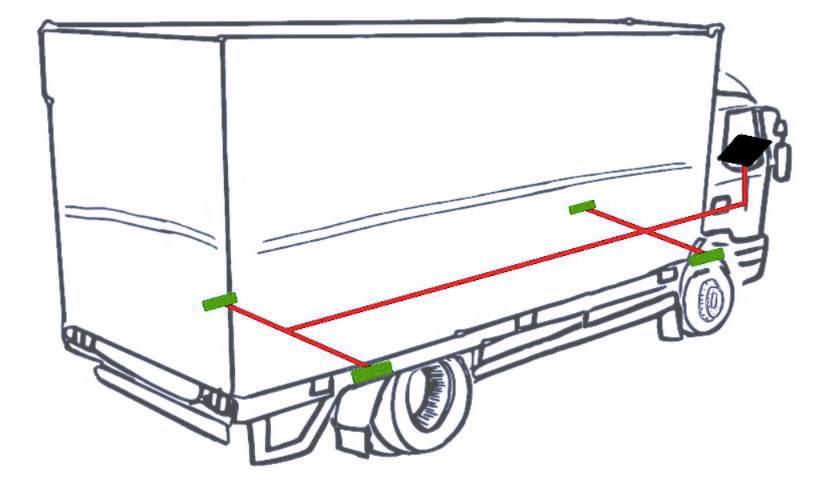

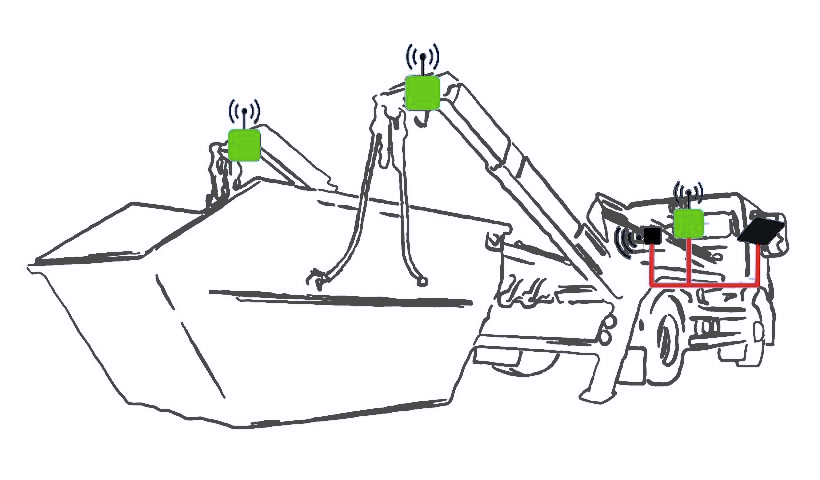

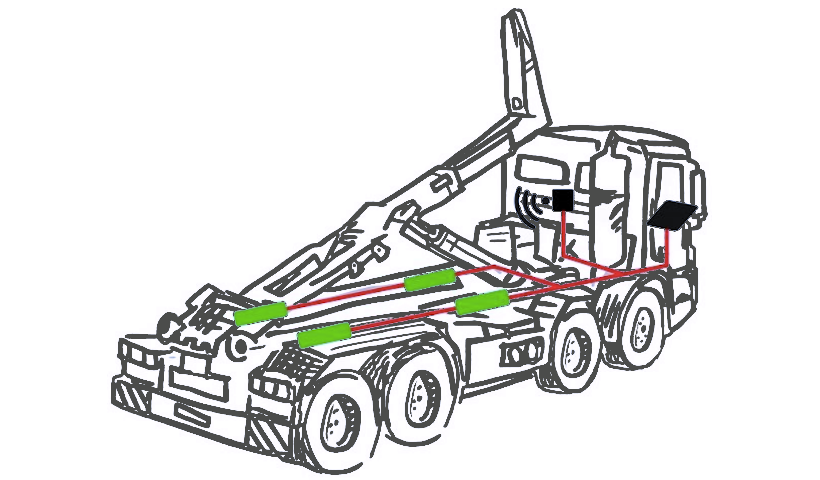

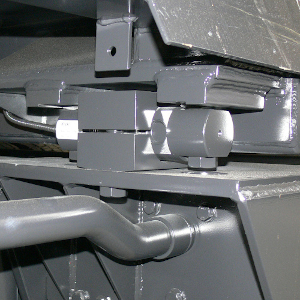

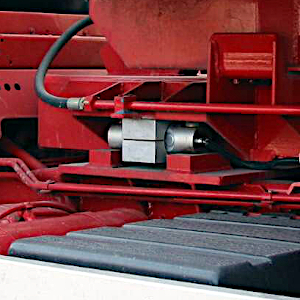

KWS is one of the pioneers in mobile weighing. 4 or more load cells are permanently installed between the chassis of the truck and the container, dumpster, or tank that sits on top. Hence the weighing cells connect the frame to the structure on top and weighing is continuous, while driving and parking. The weighing system is not susceptible to shock and does not need any fixation, i.e. It is not necessary to detach a detent to weigh. This means that you can drive and weigh without having to manipulate the weighing system. Weighing while on a slope still gives the correct weight (incline compensation).

Apart from a continuous and precise weighing of loading and unloading of transported goods or waste, the advantages are no detours to weighbridges, saving on fuel and time, easy reading, and invoicing from the terminal inside the cab of how much of a product has been delivered or accepted, partially unloading avoids uneconomic single small volume tours, recordings of weighing results avoid theft, interfacing to on-board computer and connected systems.

The results are more sales, fewer travel costs, and efficient fleet utilization.

With our partner, KWS, generizon promotes sustainable waste management, from collection to disposal. This application encourages the collection and selective sorting, and limits round trips, and therefore fuel and GHG, it essentially contributes to intelligent data collection and therefore to more sustainable planning of waste in cities.

In addition, the weighing system is dedicated to several other fields and applications, it is simple, automated, and practical.

onboard weighing systems.

KWS develops and produces onboard weighing and identification systems which are sold all over Europe and the Middle East.

KWS is one of the pioneers of mobile weighing. CEO Herbert Krickl has been working in the business since 1991.

The industry-specific customer application is the biggest priority at Krickl Weighing Systems as are the regulatory requirements. All solutions are certified (ISO 9001, TÜV, NAWI, MID) and they are continuously improved. The margin of difference for a 40t load is +/- 10kg; that puts the typical deviation for a 2-tonne delivery at +/- 1kg.

For many applications and industries standards have been developed over the years, still Krickl is happy to listen and individualize its products for the needs of a client in order to maximize the efficiency and the cost/benefit calculation. Krickl’s technicians and engineers look forward to your challenges.

typical applications and industries.

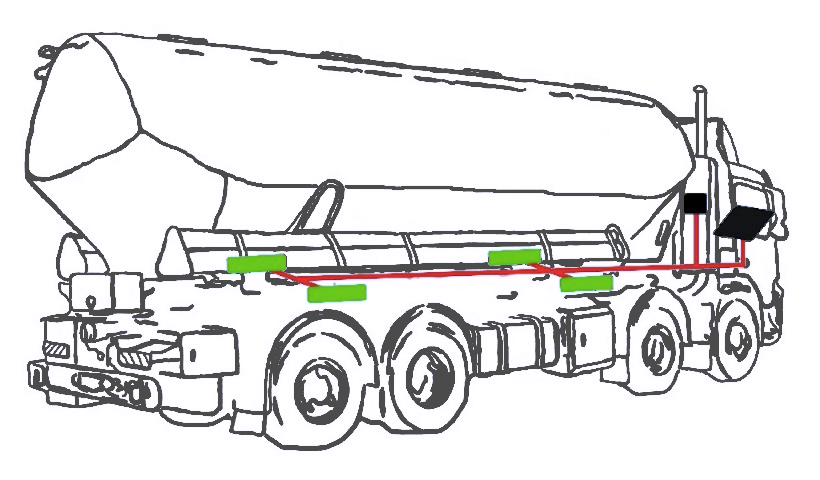

- food transports, flour, grain, animal feed, …

- fuel transportation: pellets, LPG, biodiesel, …

- waste disposal: household and industrial waste, animal carcasses, …

- other disposals: building rubble, excavation, …

- recycling: used oil from workshops and petrol stations, …

- transport of dangerous goods: technical gases, …

overview of the main applications.

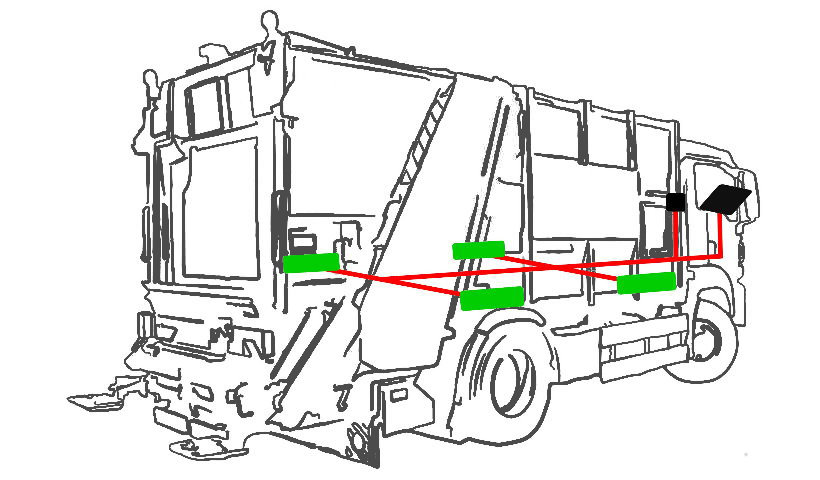

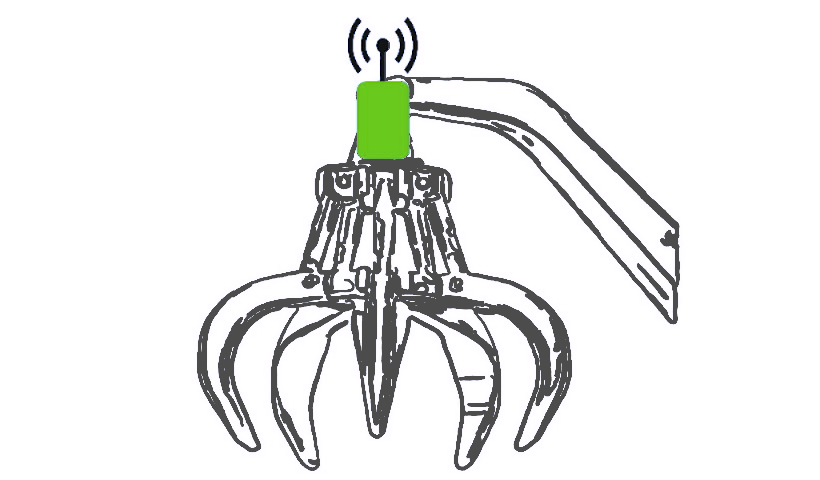

waste management/collection. KWS offers a wide range of weighing and identification solutions for vehicle-based waste disposal. The disposal process is brought up to date in an efficient manner providing big data content for continuous optimization.

animal feed and pellets. main advantage. delivery to several customers on one route. theft security. partially unloading with weighing avoids non-economic single small-volume tours.

GPL delivery. theft security. route planning. delivery by weight instead of volume. client acceptance.

agro-food.

overload control. vehicle system for payload optimization. overload protection and load distribution for use in vehicles with steel suspension or air suspension systems or a combination of the two spring systems.

gallery.

The main thing is the precise weighing of your load and user-friendly operation.

If you want to weigh the content of silo vehicles, hook lifts, skip loaders, and garbage trucks, then an onboard weighing scale is the right solution.

The body of the truck is permanently connected to the load cells which are mounted on the truck frame. 4 to 16 load cells can be installed (technically feasible). The container sits on top of the load cells. The weighing system is insensitive to pushes and impacts. You drive and weigh at the same time. Weighing while on a slope still gives the correct weight (incline compensation).

- Avoid detours to stationary weighbridges and save time and fuel. Weight measurement anytime and anywhere.

- Permanent overview of the loaded quantity.

- Control of maximum allowed weight.

- Precise weighing of loading and unloading of transported goods. Easy reading of how much of a product has been delivered or accepted.

- Partially unloading with weighing avoids uneconomic single small-volume tours.

- Permanent recordings of weighing results avoid theft. The weight is continuously measured and stored. Possible in connection with GPS data telematic and identification.

- Invoice printing directly on site of delivery.

- Interfacing with an onboard computer/USB allows comprehensive data recording.

The result is more sales, fewer travel costs, and efficient fleet utilization.

Krickl in a nutshell.

- onboard weighing range up to 40t.

- tolerance margin for 40t load +/- 10kg. typical deviation for a 2 tonne delivery +/- 1kg.

- inclination compensation.

- in Europe and the Middle East.

- since 1991.

- ISO9001:2015

- Please consult Krickl’s homepage.