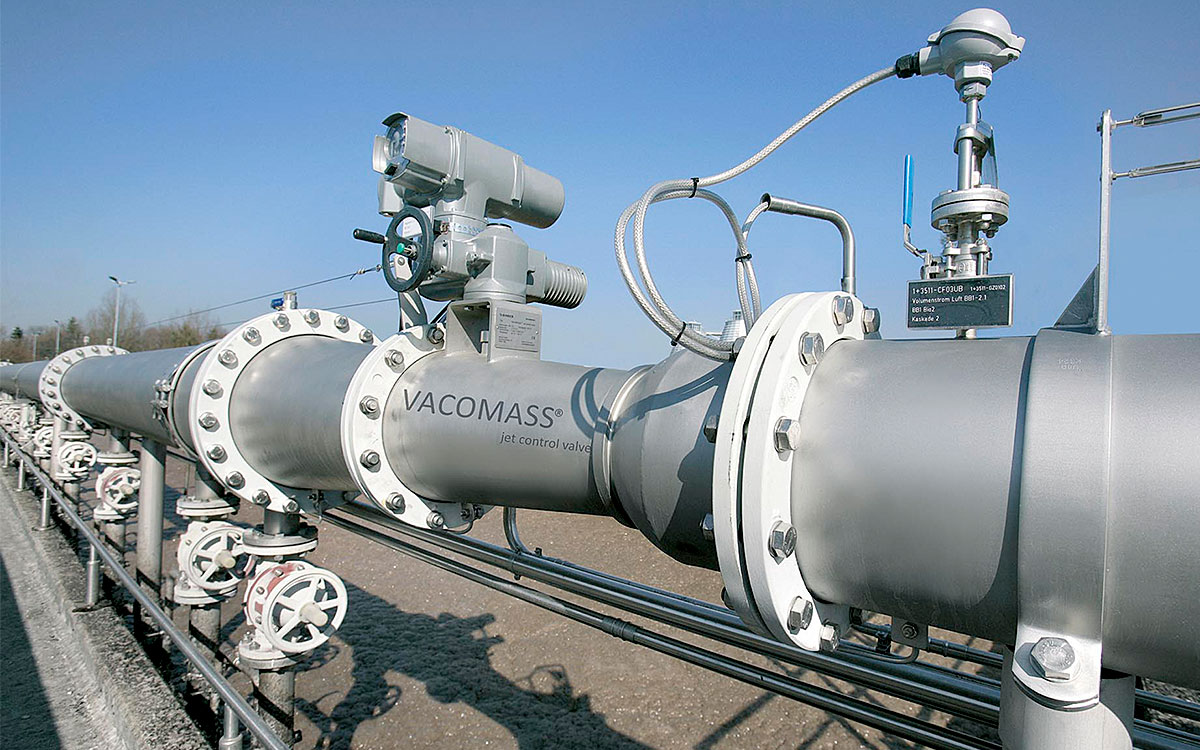

VACOMASS® control valves for aeration air in aeration tanks of waste water treatment plants.

VACOMASS® is a modular aeration control system in wastewater treatment plants (WWTP), a high-precision solution for optimizing aeration in biological wastewater treatment. Aeration is the largest energy consumer in WWTP, and the VACOMASS® system is designed to reduce this energy consumption by typically up to 20%.

The system addresses the critical challenge of balancing oxygen supply: under-aeration leads to process disruptions and missed effluent limits, while over-supply wastes significant blower energy and can compromise the denitrification process. VACOMASS® ensures that air is supplied according to the actual oxygen demand in various basins and zones.

key VACOMASS® advantages.

- Process Stability: Immediate reaction to process disruptions (like heavy rainfall) ensures even cleaning performance and compliance with effluent permits.

- Equipment protection and process safety: The system treats the entire aeration chain, assures protection of upstream blowers and downstream diffusers.

- Energy Efficiency: Significant reduction in blower power consumption through precise control and low-pressure-drop components.

- GHG emissions: Monitoring of N2O production & emissions.

- Modular Flexibility: Components can be used individually or as an integrated system, allowing for easy retrofitting in existing plants.

VACOMASS® precision control valves.

Binder offers several valve types optimized for different needs:

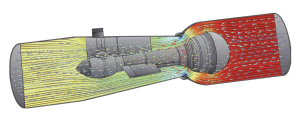

- VACOMASS® jet control valve: The flagship valve, featuring a unique 360° aerodynamic design that allows for pressure recovery of up to 75%. It provides a linear operating characteristic over its entire stroke, enabling minute control steps (0.15%). Its design also acts as a flow conditioner, allowing for extremely short installation lengths.

- SDCV square diaphragm control valve, proven for years with a stable proportional operating characteristic.

- EDCV elliptic diaphragm control valve, designed for high flow rates with minimum pressure drop and low noise emissions.

VACOMASS® thermal mass flow meters.

VACOMASS® flow meters monitor air flow under standard conditions directly, without requiring additional pressure or temperature compensation. Because they do not generate a significant pressure drop, they do not increase blower energy costs.

Airflow meter are installed downstream of the blowers, in header pipes to individual aeration basins, in branch lines to individual aeration zones (monitor diffuser aging).

- For very large pipes a multipoint-sensor-system VACOMASS® flow meter multi may be required.

- Hot Tapping Units: Allow for the safe removal of flowmeters during active operation for maintenance without losing air.

- Simultaneous Flow Profile Correction: In compact installations where the meter is placed directly upstream of a valve, the electronics can automatically correct the reading based on the valve’s stroke.

intelligent control and software – flexcontrol.

The VACOMASS® flexcontrol is a PLC-based hardware platform that acts as the “brain” of the aeration system. Its features are categorized into high-precision air regulation, energy optimization for blowers, and proactive maintenance for sensors and diffusers.

Core Aeration Controllers:

- Aeration Controller-DO: A sophisticated AI-driven controller for plants with air flow meters. It uses self-learning algorithms to calculate the exact air flow rate and valve stroke needed for both continuous and intermittent aeration.

- Aeration Controller-Q: Similar to the DO version but focuses on achieving a specific air flow rate setpoint transmitted from a master PLC.

- Aeration Controller-LITE: Designed for smaller installations that lack air flow meters. It uses classic Dissolved Oxygen (DO) feedback to adjust valve positions based on setpoint deviations.

Efficiency & Blower Optimization ensures air is produced with the lowest possible energy expenditure:

- econtrol (MOV/MIV): This is the Most Open and Most Important Valve logic. It calculates the minimum header pressure required to satisfy the basin with the highest demand. By keeping at least one valve fully open, it prevents blowers from working against unnecessary resistance.

- econtrol Blower: An AI-powered Master Control Panel (MCP) that can manage different types of blowers. When combined with aeration controllers, it enables Predictive Valve Control (PVC), allowing the valves and blowers to adjust in sync before pressure imbalances occur.

Dynamic Setpoint Management modules calculate the ideal oxygen target based on real-time pollution loads:

diaphragm control valve.

- DO-SET (NH4-N / N2O): Adjusts the oxygen setpoint based on Ammonium (NH4-N) concentration or load. It can also integrate Nitrous Oxide (N2O) data to minimize greenhouse gas emissions.

- DO-SET KASK: Optimizes load distribution across sequential (cascading) aeration tanks.

- VAer-SET: Specifically manages air supply for “swing zones”—basins that switch between aerobic and anoxic phases.

Maintenance Modules, diffuser protection:

- DIFF-FLEX / PRESS-REL: Automates the mechanical cleaning of diffuser membranes by flushing them with air or releasing pressure to dislodge biological growth.

- DIFF-CHCK: A long-term monitoring tool that tracks the pressure drop across diffusers to alert operators when they are becoming too clogged to operate efficiently.

- SENS-CHCK: viability checks for DO sensors.

- Plausibility Monitoring.

Auxiliary Process Control:

- Controls the ON/OFF status of agitators, pumps, and flaps.

- Controls Return Activated Sludge (RAS) rates.

- Manage the mechanical movement of fluids and chemicals.

- And more.

modernization and retrofitting.

The system is highly effective for modernizing older plants. For example, replacing standard gate valves (which often operate in a restricted 10-30% range with high pressure drops) with VACOMASS® jet control valves can significantly reduce header pressure and energy costs without needing to expand existing pipelines . Custom calibration in the CAMASS® Calibration Lab ensures that the system is optimized for the specific piping layout and local conditions of the plant

more information. Binder. datasheet VACOMASS® Jet Control valve. VACOMASS® system.