Hydreatio/Rotreat.

Founded in 1993 and specializing in proprietary membrane systems for wastewater and leachate treatment, Austrian company Rotreat Abwasserreinigung GmbH, has been a long-standing partner of Generizon. Acquired by Hydreatio in 2023, Rotreat’s core technology, the Radial Channel Disc Tube (RCDT) module system—an innovative osmosis device for wastewater, leachate, and industrial effluents—remains a key offering. This RCDT system provides a CAPEX-efficient alternative to traditional biological nitrification processes. Hydreatio has integrated Rotreat’s technology with its own comprehensive water treatment services.

The DT module technology (disc tube module), on which the RCDT technology is based, has been used successfully since 1985 as a membrane filter in the desalination of seawater and since 1987 in the treatment of wastewater, leachate and many other industrial effluents.

pure water from any source at any location.

The reverse osmosis plant program is standardized and detached with a capacity from 400 to 50,000 l/h. The system pressure of the plant is usually at p= 90 bar.

A lot of experience has been accumulated over 30 years on a great many osmosis plants with different water qualities.

Over 100 million m3 of wastewater have been treated.

These plants are positioned internationally. The RCDT technology is successfully purifying wastewater worldwide.

RCDT technology is today used in the following countries: Austria, Slovenia, Finland, Spain, Portugal, Italy, Malta, Greece, Turkey, Germany, Romania, Brazil, Czech Republic, China, South Korea, Tunisia, Mexico, Baltic States, Hungary, India, Sri Lanka, Russia, Croatia, and Australia.

Due to the unique design of the new RCDT 2.0 module, a membrane lifetime of up to 5 years has been experienced.

radial channel disc tube module – RCDT.

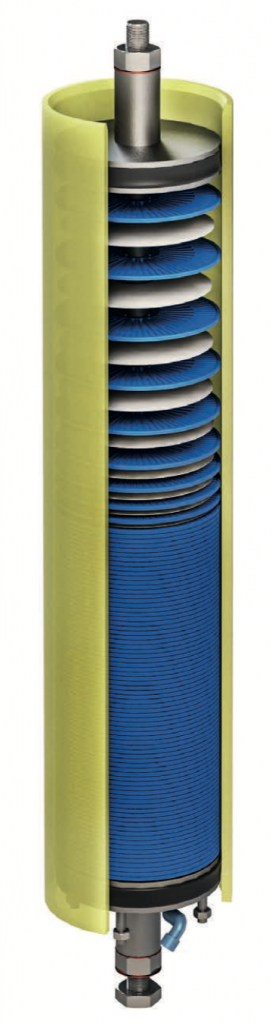

The so-called ”RCDT module” (Radial Channel Disc Tube module) is the most advanced product in plate module technology.

This module consists of a pressure tube and hydraulic discs which are held by a center tension rod. Membrane cushions lie between every two discs.

Owing to this special construction, open flow channels are formed between the hydraulic discs and the membrane cushions, where the raw solution concentrates.

The individual channels are joined together by openings in the discs, which are arranged in an annular pattern so that the feed water flows radial across the membrane cushions, alternately from the inside towards the outside and reversibly.

RCDT reverse osmosis is a cross-flow filtration process, i.e. driven by pressure: untreated water flows across an active layer (membrane) at high velocity and the filtrate flow passes through the membrane in vertical direction.

Membrane separation is a physical process, i.e. the components to be separated undergo neither thermal, chemical, nor biological changes. Reverse osmosis allows the separation of low-molecular substances and inorganic salts.

Usually, RCDT reverse osmosis is operated up to 90 bar. In addition, Rotreat offers a special high-pressure technique up to an operating pressure of 160 bar, recovery rates up to 90% are possible. Reverse osmosis allows the separation of low-molecular substances and inorganic salts.

La production de membrane et de module est selon les normes ISO 9001.

modular systems to treat landfill leachate.

All plants are tailor-made according to the customer’s demands and the specifics of the wastewater and leachate. Four standard modular plants, which can treat leachate volumes from 0.5 m3/h to 15 m3/h, form the basis of the system.

The modular system design allows the construction of plants for bigger water volumes.

If required, these plants can be equipped with permeate stages (2nd RO stage) to ensure, that even in the case of high pollutant concentrations the standard requirements are met. To increase the permeate yield (= minimization of the concentrates to be disposed of) concentrate stages with high-pressure technology up to 160 bar are offered.

Recovery rates up to 90%

The energy consumption of the new RCDT module is particularly low, 6 – 8 kWh/m³ leachate (wastewater) treated, very low compared to other treatment systems. Multi-stage treatment systems however can reach much higher energy consumption, up to 60 kWh/m³ (eg. with evaporation).

applications and industries.

- Purification of landfill leachate.

- Treatment of effluents from the pharmaceutical industry.

- Purification of industrial wastewater.

- Desalination of seawater. production of drinking water.

- Reject the treatment of spiral reverse osmosis.

- Treatment of effluents from the textile industry and the dyeing process.

- Treatment of tannery effluents.

- Treatment of wastewater from distilleries.

- Mine wastewater treatment.

- Membrane filtration for municipal wastewater treatment.

low service. high availability.

pretreatment and posttreatment.

Comprehensive wastewater treatment necessitates a deep understanding of both the characteristics and composition of the influent. While knowing parameters like conductivity, Chemical Oxygen Demand (COD), Biochemical Oxygen Demand (BOD), and the presence of metals, oils and salts is crucial, it’s equally vital to determine the specific forms in which these constituents exist. This detailed knowledge is essential for effective process design.

To this end, obtaining a sufficient volume of leachate from the pond allows the Hydreatio team to perform thorough testing of their treatment processes and chemical applications. This hands-on analysis forms the foundation for a tailored system design. The design process encompasses several critical stages:

- Pretreatment Design: This initial phase focuses on preparing the leachate for subsequent filtration. It involves: * Coagulation: Introducing chemicals to destabilize suspended particles, promoting their aggregation. * Flocculation: Further aggregating the destabilized particles into larger, more easily removable flocs. * Sedimentation: Allowing heavier solids to settle out of the liquid phase. * Prefiltering: Removing larger solids through coarse filtration.

- Main Filtration Element Design: This stage involves selecting and configuring the appropriate membrane filtration technologies: * Microfiltration (MF): Removing suspended solids and larger bacteria. * Ultrafiltration (UF): Removing smaller particles, including viruses and macromolecules. * Nanofiltration (NF): Removing multivalent ions and some organic compounds. * Reverse Osmosis (RO): Removing dissolved salts and most remaining contaminants, producing high-purity water.

- Ammonia Stripping Plant Design: If ammonium ([NH4]+)is present at significant concentrations, an ammonia (NH3) stripping plant is designed to remove it. This typically involves raising the pH and temperature to convert ammonium to ammonia gas, which is then removed from the liquid.

- Post-Treatment Design: This final stage addresses the management of the concentrated waste stream and the refinement of the treated water: * Drying Pans: Allowing the concentrated waste to evaporate in open-air pans. * Solar Thermal Drying: Using solar energy to accelerate the evaporation process. * Condenser: Capturing and condensing evaporated water vapor. * Cooler: Reducing the temperature of the treated water, if necessary, to meet discharge or reuse requirements.

pilot container – test station.

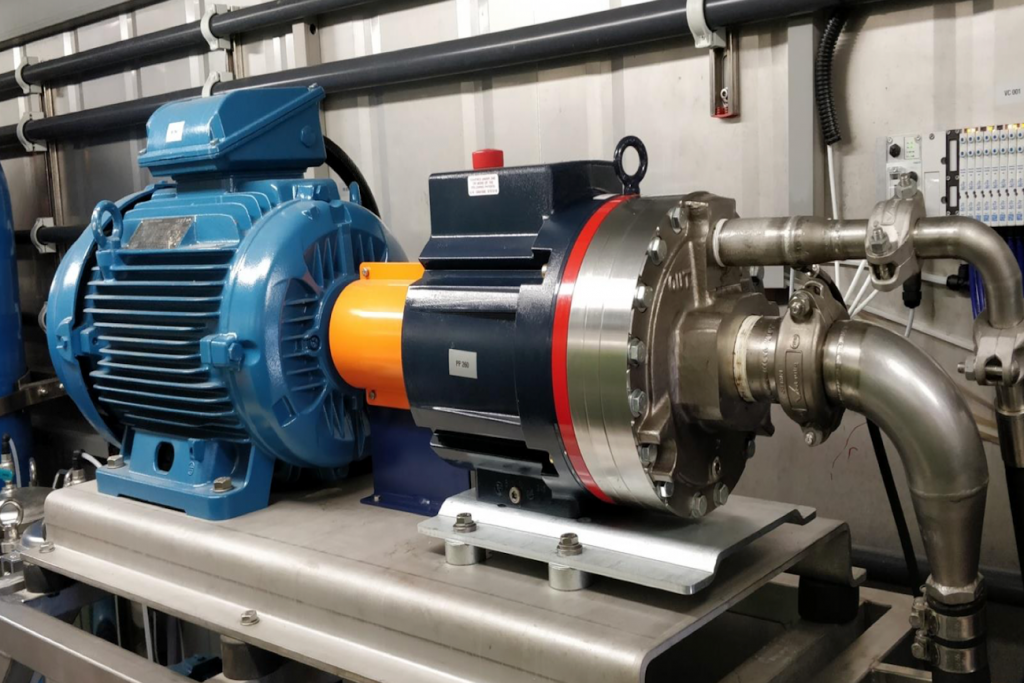

It is generally a good idea to test for specific leachate and wastewater sources. Rotreat’s test units, either fully functioning container systems, or one single RCDT tube and pump system on a skid, include delivery, installation, configuration, running, and reporting on test results.

pilote 60m3/day.

one tube test skid. 1m3/day.

characteristics.

- One or two months for each site. dump.

- Test several/all sample points.

- At the same time analyze the leachate, the permeate, and the concentrate.

- Test the limits of the technology. go to and beyond limits.

- Configure the installation afterwards, and adapt it to the context of the Moroccan leachate.

- Dimensioning and proposal of the unit on an industrial scale. roadmap to treat all the leachate on a site.

- Work on the business proposal.

- Payment per processed cubic meter.

- Per cubic meter of clean water sold to the city.

Rotreat Abwasserreinigung GmbH in a nutshell.

- RCDT technology successfully purifies wastewater worldwide.

- Landfill leachate. 15,800 m3/day.

- Industrial wastewater. 21,300 m3/day.

- Rotreat.net

- Hydreatio.com.