The green hydrogen economy has been announced with a lot of hype, and we will see what will happen, if it develops, and whether it’ll carve out more than a small part of the low-carbon economy.

To phase out fossil fuels and limit global warming, green hydrogen has for some become the new wonder vector, the silver bullet, the Swiss army knife to decarbonize. Is it all just hopium, a mix of hope and opium?

Theoretically, hydrogen, as a molecule instead of an electron, has the potential to facilitate transport, storage, and re-conversion into power. In practice, it is physics and economics that will prevent us from using green hydrogen for much else than for what we use grey & black hydrogen today.

There are some sectors of the economy (e.g. fertilizer), that are in true great need of and will have green hydrogen production applications at scale in the future. These are foremost those sectors that need and use (mainly grey) hydrogen today (fertilizer, some chemicals, steel, some petroleum, …).

For many other industrial sectors, like transport, shipping, industrial, and home heating, the most likely decarbonization vector is electrification with renewable sources, as this will be cheaper, more secure, and more sustainable.

Green hydrogen will be produced in those countries (e.g. Morocco) where renewables, wind, and solar are in abundance and hence cheap. Industry in need of the green hydrogen molecule will move to these countries, and there will be, most likely, only a little shipping of hydrogen, neither in liquid nor in compressed form, not in pipelines, not through fancy chemistry, it seems very complicated at this stage.

what is hydrogen?

Wikipedia: Hydrogen is the most abundant chemical substance in the universe, constituting roughly 75% of all baryonic mass. Most hydrogen on earth exists in molecular forms such as water or organic compounds. Hydrogen gas forms explosive mixtures with air in concentrations from 4–74%. This reaction produces as byproduct water, it releases no CO2 to the atmosphere (decarbonization).

2H2 + O2 → 2H2O + energy

When burnt with air it releases small quantities of nitrogen oxides, NO2 and NO3.

how much hydrogen is produced today?

100 million tons of hydrogen is consumed in industrial processes around the world. This hydrogen generation market is valued at over ≈150 billion USD plus a business. (IEA Global Hydrogen Review 2023)

There are four main sources for the commercial production of hydrogen: natural gas (produced by steam reforming of methane or natural gas), oil, coal, and electrolysis. 6% of the global natural gas is used to produce hydrogen, 2% of global coal, combined 830 MtCO2Eq/year is the GHG emissions impact of the current hydrogen economy, which equates to 2.3% of global carbon dioxide (CO2) emissions stemming from fossil fuels and industrial activities.

Only a minor role is currently played by electrolysis of water which is due to the high electricity input necessary. Biomass and biogas could also serve in several ways as primary inputs in H2 production.

origins/production of hydrogen. colors of hydrogen.

- grey hydrogen from fossil fuels,

steam methane reforming (SMR) of natural gas (62%),

CH4 + H2O ⇌ CO + 3 H2 (Syngas),

CO + H2O ⇌ CO2 + H2

this is currently the cheapest source of hydrogen,

~1.5-2 EUR/kg depends on the price of natural gas.

during the production of 1 ton of hydrogen, 5 to 6 tons of CO2 are released as greenhouse gas emissions to the atmosphere. - brown/black, from coal (21%).

- blue hydrogen, from natural gas via SMR if CO2 is captured, carbon capture, utilization, and storage (CCUS) cost money. It is hard to think this will become feasible in the next decades.

- green hydrogen is produced from renewable electricity, wind and solar, and electrolysis of fresh water. Electrolysis H2 amounts to next to nothing (≈0.1%) today, and not all is renewable. Production costs are still 3.5 – 5 EUR/kg but may be coming down with green electricity generation prices declining. The cost of electrolysis shall be coming down too, maybe and eventually, as global subventions work through and technology develops and scales up, alkaline water electrolysis, proton-exchange membrane (PEM) water electrolysis, and high-temperature water electrolysis, etc.,

For green H2 to replace the current ≈100 Mt/year of used grey/black hydrogen requires building enormous new generating capacities of green electricity (renewables, solar in the desert, etc.), it requires understanding the new H2 electrolysis technology at scale, it requires financing and addressing the multiple security concerns. Everybody out there is still learning, don’t expect miracles … soon. - pink hydrogen, when electricity is of nuclear origin.

- hydrogen from carbonization processes.

- hydrogen as a byproduct (16%) of other chemical processes, caustic soda, chlorine, etc. In some cases it is free.

So we shall be seeing hydrogen production go primarily green by 2050. With solar and wind becoming much cheaper and green electricity available in abundance, green hydrogen might also become competitive, …

- if a market for green H2-based products develops,

- if the alternative, fossile-based products become regulated or taxed,

- if polluting is penalized,

- if we stop polluters from using the atmosphere as free public sewer (Paul Martin).

agricultural use of hydrogen.

- ammonia feeds the world.

- 30% or more of global hydrogen production is used to produce ammonia for fertilizers.

- ammonia production for fertilizer, NH3, Haber–Bosch process, nitrogen fixation,

N2 + 3H2 → 2NH3.

H2 from gray steam methane reforming (SMR) is the main source.

blue H2 is more expensive than gray H2, if the price for pollution allowances (CO2 emission certificates) increases, this may become viable. - green ammonia comes from green H2, a fertilizer from green ammonia decarbonizes agriculture, first needs to go first, we need to continue eating.

- ammonia production is 160 million tonnes per year; four-fifths of this goes into fertilizer production.

- industrially (via SMR+Haber Bosch) produced ammonia is responsible for ≈1 percent of global greenhouse gas emissions, i.e. ≈400 million tons of CO2.

industrial use of hydrogen.

Apart from its use in the production of ammonia and fertilizer, hydrogen has widespread industrial applications

- oil refining of crude and intermediate oil products into refined fuels, hydrogenation, hydrocracking, removing sulfur, etc.,

- in the production of carbon steels,

- as a raw material in the chemical industry,

- for methanol synthesis, CH3OH, which is used in the manufacture of many polymers,

- as a reduction agent in the metallurgic industry, hydrogen is needed to replace the chemical reductant carbon monoxide,

- for metal alloying,

- for flat glass production,

- in the electronics industry, etc.

heat use of hydrogen.

Hydrogen could transform the global energy system as a natural substitute for fossil fuels, with its potential major role as a zero-carbon energy carrier, and it is the oil industry that is looking to adapt, to remain relevant. Zero-carbon fuel and the greening of production processes are interesting subjects to the

- steel industry: for heat, as the traditional blast furnace method releases large amounts of carbon. In many cases has the steel industry already begun to go all-electric, high-temperature arc furnaces for steelmaking are already quite popular, and resistance heating in rolling mills similarly replaces ovens, hydrogen remains relevant as a chemical reductant agent.

- cement industry,

- ceramics,

- medium-grade heat, like in the paper industry, is better served by electricity,

- medium-grade heat, plastic production, better served by electricity,

- there is a simpler and more efficient electric solution for many applications.

Just as there are theoretical applications for hydrogen in industrial heating, many other electrical and biofuel alternatives are more affordable and secure. In fact, electrical alternatives are being deployed in many places, not so (yet) hydrogen.

Any change in heat generation equipment away from burning fossils will be expensive. But existing fuel boilers and natural gas compressors will not work readily for hydrogen, any such transition will be equally expensive.

Changing directly to electrical heat-generating systems will in most cases be easier, less costly, and more secure.

hydrogen in mobility.

The transport sector is in many ways similar to the industrial heat consumers, in that it looks as another obvious easy play for H2, replace one fuel with another one. But things are complicated, and expensive.

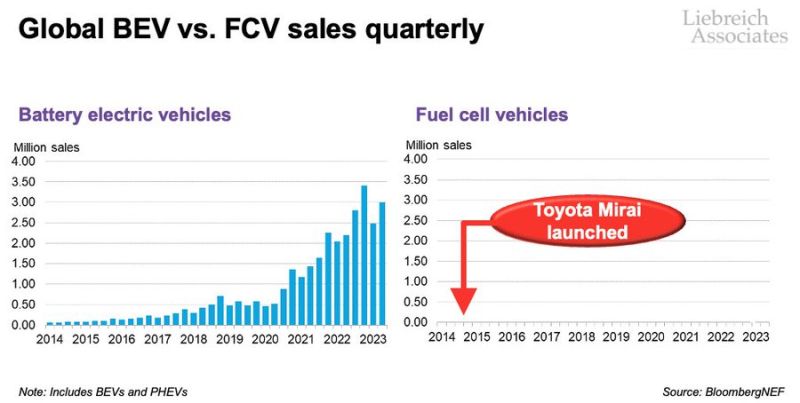

And then BEV (battery electric vehicles) took off, and if powered by renewable electricity from solar and wind they win hands down on emissions.

Starting with the same amount of green electricity BEVs are 70-80% more efficient than FCEVs (fuel cell electric vehicles), losses occur in the production, transport, compression, and reconversion of electricity to hydrogen to electricity. Apart from other hydrogen infrastructure that needs to be built to transport and store hydrogen, there will be a need for three times the green power capacity if all transport goes hydrogen.

Other facts:

- FCEV cars, and buses, for large transport and long distances, trains, etc., are above all more complicated the BEVs.

- one kilogram of hydrogen corresponds to around three liters of diesel or fuel.

- three liters of diesel remain less than 3 kilograms, at ambient temperatures.

- one kg of hydrogen at ambient temperatures takes up a volume of around 11 m3, which is the quantity needed to drive 100 km in a passenger car.

- such is the low volumetric energy density of hydrogen. The energy density per unit mass is excellent – but not per unit volume. For a 500 km journey, an FCEV will need about 5 kg of hydrogen. At 700 bar a storage system would still have a volume of about 200 liters or 3-4 times the volume of a gas tank. Today it seems FCEV vehicles have completely lost it to BEV.

- 700 bar storage is neither easy, secure, cheap, and it takes a lot of electricity to compress to this pressure.

- pure H2 internal combustion engines too seem like an option but are an even bigger waste of energy in transportation.

- easier and more stable is the use of ammonia, a stable fuel, and already used in shipping today, just ammonia takes up more space than diesel; ammonia is also VERY toxic.

power use of hydrogen.

- fuel cells.

- internal combustion engines.

- we are taking in both cases of reconversion to power.

- H2 harbors the potential for decentralization and flexibility, maybe through a pure H2 CHP, when heat is a co-driver…

This roundtrip, electricity-hydrogen-electricity costs some 70-80% of electricity.

It needs foremost cheap clean electricity. A renewable’s many times overcapacity may one day make hydrogen re-powering an option. This is true for any power-to-X variant, to become a significant part of the low-carbon economy.

Hydrogen can then theoretically be stored and transported for reconversion into electricity, thus closing the circuit again. This may be an option for off-grid, far away, remote applications, but it is easier to deliver the same with biofuels, this is the competition. Biofuels will become available once most transport switches to electric.

storage and transport of hydrogen.

- blend with natural gas (including hydrogen) into the gas grids (8% in past, now 25-40% seems possible), the problem is the much higher volume that needs processing, the more we add hydrogen the less there is energy content per volume.

- pure H2 pipeline network, conversion of old networks (new compressors, new pipings), new H2 pipeline networks, all is expensive, it needs another driver to become feasible.

- H2 piping is the transportation of power, as a seemingly lossless carrier when compared to electricity (like NG), hydrogen transport by pipeline has many technology hurdles to overcome, the future will tell.

- guarantees of origin for blue and green hydrogen is an issue (maybe blockchain, or maybe this is hype,…),

- liquified H2, cryogenic, -253 °C, energy-intensive, for trucking, train, ship transport, if well-insulated H2 stays liquid for 2 weeks, blow-off of 1% per day!

- pressurized hydrogen gas, compressed to 700 bar, expensive tank (carbon fiber, spheric), and compression, many spheric tanks can be combined on one trailer.

Direct storage of electricity in lithium-ion or Li-ion batteries is the competition. These batteries are widely applied already and seem practical. New battery technology is also out there. Batteries are very much recyclable, the preciousness of the raw material is the driver.

A different kind of storage that is well known is pumped hydro energy storage, it can be readily scaled to any required storage capacity at a known and affordable cost. For more than a century this technology has been applied with a lot of success.

Hydrogen is in competition with electrify everything. Competition is what will define whether hydrogen as envisioned by some will take off.

the future? clean electrolysis.

Wind and solar electricity production cannot be controlled in the same way as we switch on and off some other power plants. Timely production can be estimated in advance (we have a good grasp of the weather pattern), but it cannot be controlled.

As more green capacity comes online every day, the more we need to manage intelligently these imbalances between production and consumption, stabilize the grid, and smooth out the bumps (smart grid).

Overcapacity and at times an abundance of green renewable energy production would at times render really cheap electricity, this supply overhang of green electricity is looking for storage, or for new demand.

It may be then that it is economical to produce hydrogen via water electrolysis; that the production of green hydrogen seems like a great solution, as hydrogen is in principle transportable and storable (power to H2).

But a lot has to happen politically, and institutionally, the mechanisms have to be created so that huge investments will be undertaken, and a lot of new technology will have to be made to work first.

Electrolysers reportedly don’t like being turned on and off.

hydrogen from biogas.

Instead of electrolysis, H2 is produced using the known steam methane reformation process (SMR). In the process, natural gas reacts with water vapor at high temperatures and pressure, resulting in hydrogen and CO2. Steam reforming of natural gas accounts for most of the current world’s hydrogen supply, so the technology is already well understood.

Under current conditions (2022/10) starting with landfill gas, biogas, or sewage gas, may be the cheapest way to produce green hydrogen. The process is called biogas upgrading (BGUG) to biomethane, it involves drying and desulfurizing it in a first step, separating methane from CO2, and further purifying the biomethane, by removing all N2.

Subsequently, biomethane is treated in an SMR process in the same way as NG.

The inconveniences:

- Biomass and organic waste are always decentralized,

- SMR plants will be small, they exist but are costly, but may provide sufficient decentralized green H2 for industrial use,

- There will never be enough biomethane for the grand H2 ambitions we have.

so what is this hopium?

As described here: Hopium is a merging of the words “hope” and “opium”. When used, it means the conversion of hope into a drug that compromises our ability to analyze and make good judgments about new technology.

More on hopium:

- Paul Martin, distilled thoughts on hydrogen.

- Youtube Michael Liebreich.

- The Liebreich Hydrogen Ladder.