UIT. environmental services.

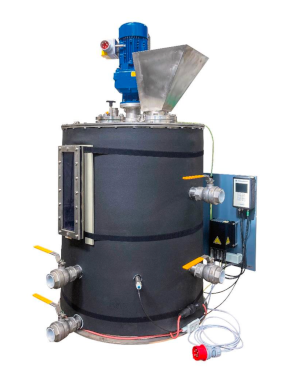

Bioreactors and biogas test equipment from UIT, Umwelt- und Ingenieurtechnik GmbH, generizon’s partner, are manufactured in Dresden. UIT produces all systems to the highest quality standards and ships them to customers worldwide.

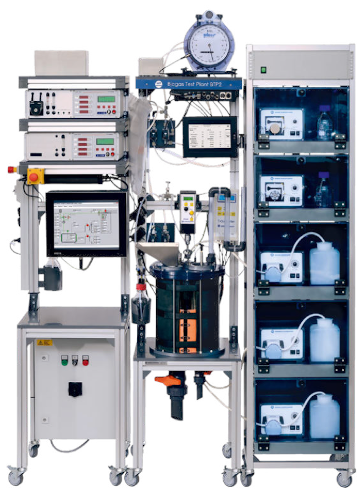

bioreactor BTP2. biogas test plant. the base and the industry standard.

The biogas pilot plant BTP2 is the base system for substrate testing and biomethane gas potential tests. Furthermore, this system is ideally suited for product development (enzymes, nutrients) or for process optimization. This is a modular compact basis test plant, extensive optional equipment can be added e.g. SENSOcontrol or optional pumps for feeding or controlling the pH.

features:

- glass reactor with different working volumes.

- continuous operation with AUTO feeding.

- electrical heating.

- two-level stirrer with gas-tight shaft.

- gas bag to collect gas samples.

- measurement equipment: gas quantity, pH / Redox / temperature.

- SENSOcontrol with touch panel.

- download.

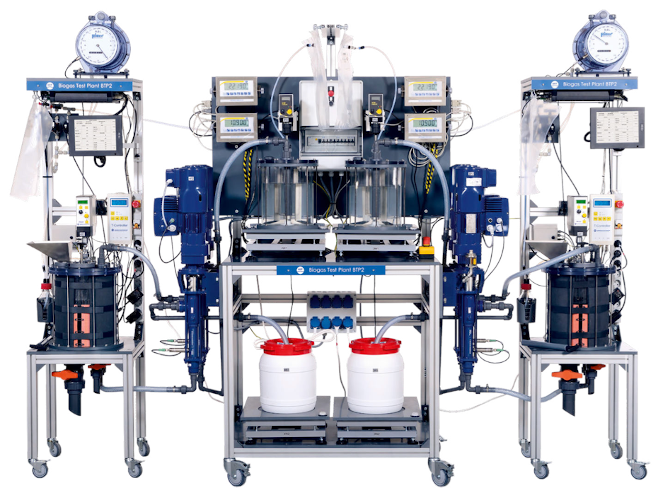

BTP2-analyzer. basic biomethane test plant with gas analyses module.

The biogas / biomethane pilot plant BTP2-analyzer is the first upgrade of BTP2 and is used mainly in research as well as for practical substrate or gas potential tests.

The BTP2-analyzer is a standard Biogas Test Plant with an additional gas analyzer to measure the parameters like CH4, CO2, O2, H2S, and more. In contrast to the BTP2-control, this system is not expandable with additional reactors but is characterized by extensive basic equipment, such as the SENSOcontrol system that also controls the gas analyzer and detects the gas quality parameters automatically, or optional pumps for feeding or pH control.

Furthermore, this system is ideally suited for research, product development (enzymes, nutrients), or process optimization.

extension of features:

- measurement equipment.

- gas quantity.

- pH. Redox. temperature.

- gas quality measurement system.

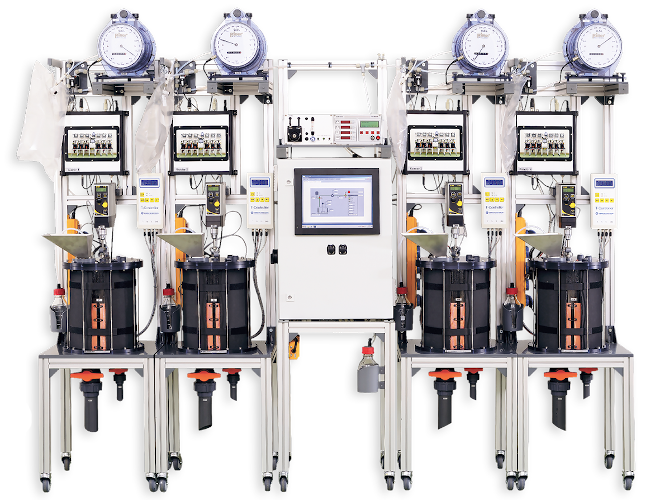

BTP2-control. biomethane potential test. ideal for research.

The fully automated bioreactor plant BTP2 control is used in research as well as for practical substrate or biomethane gas potential tests, product development (enzymes, nutrients), or process optimization. This system is modular and equipped with one gas-quality analyzer module. Gas volume and gas quality are simultaneously and automatically measured for each reactor.

The BTP2 is expandable, it is possible to connect up to ten reactors with only one gas-quality analyzer. One central computer in combination with a multiplexer unit enables an independent test procedure for each individual reactor.

UIT delivers reactor test plants from 2.5-liter reactor volume up to 1,500-liter reactor volume with different ranges of measurement and control equipment.

BTP2 control, up to 10 biogas test plants managed through one control unit.

features and extensions:

- up to 10 bioreactors on one gas quality measurement system.

- glass reactor with different working volumes.

- continuous operation with AUTO feeding.

- electrical heating and optional cooling.

- two-level stirrer with gastight shaft.

- dosage pumps for pH control.

- gas bag to collect gas samples.

- measurement equipment. gas quantity. pH / Redox / LDO / temperature. gas quality measurement system.

- SENSOcontrol with touch panel.

SENSOcontrol. data acquisition and control unit.

The universal automation system SENSOcontrol is used for data acquisition applications and control of the units (pumps, mixer) in the test facility. An intuitive touch screen is integrated for user-friendly parameter configuration and real-time visualization of the measured data.

Gas volume and quality are measured simultaneously and automatically for each reactor.

accessories and add-ons.

- test plants for experiments under sterile conditions.

- eccentric screw pumps suitable for larger quantities and particle sizes.

- many more additions are possible, for your special applications.

UIT in a nutshell.

- the standard for laboratory biogas test plants.

- world-class quality.

- UIT BTP2 catalog download.

- UIT web.