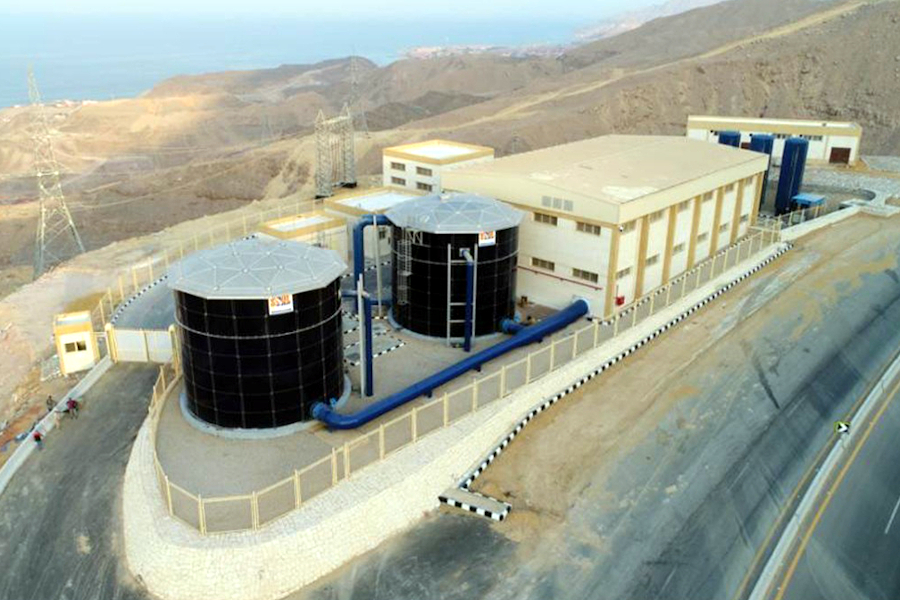

potable water storage for desalination plants.

Steel-enameling is a thermal process in the enameling furnace at above 800°C. A glass layer forms on the outside that will bond strongly with the steel in a chemically-physical fusing process. The result is a tank that benefits from the outstanding characteristics of both materials.

- glass protects from corrosion.

- steel gives strength and flexibility.

- impact and abrasion resistant.

- hygienic surface.

- no bacteria on the surface.

- temperature resistant.

- design life of over 35 years.

- maintenance free.

water is too precious. enameled steel water storage tanks.

A lot of energy, investment, and effort is put down to pumping water from far, from underground aquifers, from the sea employing desalination plant technologies, then conditioning and transporting it, and finally… We prepare the finest and most sacred good, clean drinking water, and it shall be stored and preserved in the best and most secure places, untouchable from the elements, this is what GLS Tanks stands for.

features and benefits of GLS Tanks over concrete.

- concrete will corrode → maintenance, more cost.

- additional protection (coatings, linings, etc.) is needed for concrete.

- most of the time such coatings are not resistant and come off, as they do not stick to the concrete surface entailing high repair costs.

- GLS sheets undergo a strict factory testing regime, leading to guaranteed on-site quality.

- concrete quality is dependent on many variables, there is always a high risk of bad quality of the finished product.

- GLS Tanks have a modular bolted design: quick erection times → reduced labor and plant costs.

- concrete tanks are not as easy to construct → higher construction costs.

- concrete tanks are bulky and awkward to ship → shipping to the site can be very difficult and expensive.

- GLS tanks can also be extended and relocated with relative ease, giving the owner even greater long-term versatility.

- concrete tanks are not so easily adapted or extended → limited flexibility.

- GLS tanks are available in various colors → satisfy local regulations and give a better appearance.

- concrete tanks can be an eyesore, with little choice in colors.

- GLS sheets have “Zero Discontinuities” → no voids in contact surface → high resistance to corrosion

- concrete over time will crack: Re-bar exposed → tank failure and expensive repair.

wastewater treatment basins. enameled steel tanks.

- GLS tanks in enameled steel for sewage treatment plants (wwtp).

- short construction times.

- concrete corrodes. requiring regular maintenance costs.

- the enameled steel basins of GLS Tanks have a high resistance to corrosion, to temperature variations, without the need for maintenance.

- GLS tanks can be enlarged. relocated.

- modular.

- any size.

- no maintenance.

GLS Tanks in a nutshell.

- state-of-the-art manufacturing methods.

- international norms and standards.

- outstanding quality guaranteed.

- 95% is exported.

- 35 years of history.

- GLS tanks on the web.